TPTVC/1.5kW Computer Controlled 1.5 kW Steam Power Plant

The Computer Controlled 1.5kW Steam Power Plant, "TPTVC/1.5kW", represents a laboratory scale power plant, guaranteeing a great similarity with a real system. It offers many practical exercises to familiarize the student with the operation procedure of a steam power plant with process control. Besides, it has different optional modules to adapt to the needs of each working place.

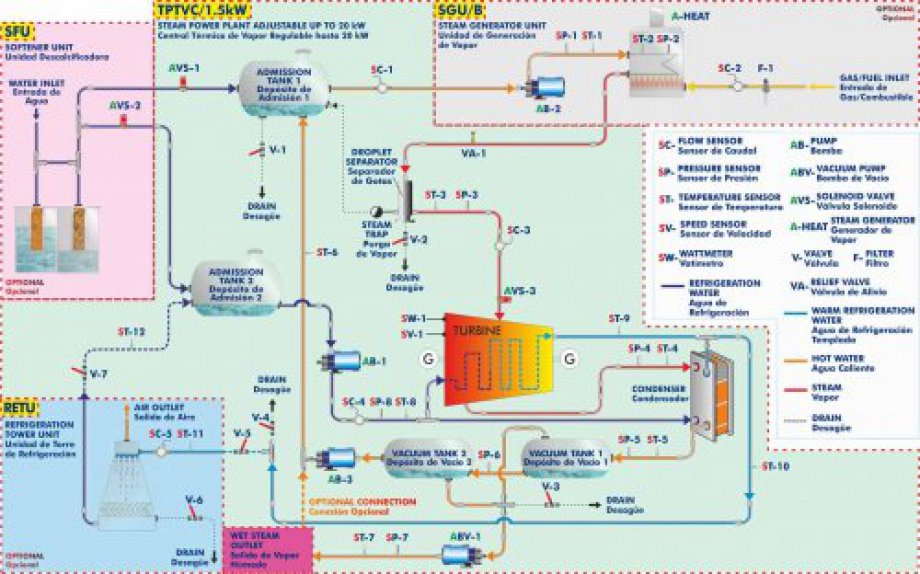

The process starts with a pre-treatment of the water to avoid the introduction of hard water to the process. EDIBON suggests the Softener Unit, "SFU", as an OPTIONAL unit, to remove the salts, impurities and other substances that may dirt the inside of the steam plant components.

Softened water can be directed towards two tanks (inlet tanks) through two computer controlled solenoid valves. The first tank stores the water for the main generation circuit and the second tank stores the water used in the refrigeration circuit.

The water of the first inlet tank is introduced by a computer controlled pump in the steam generation system, after passing through a set of sensors that collect information about the inlet temperature, pressure and flow to the generator. For the steam generation, EDIBON recommends the OPTIONAL Steam Generator Unit, "SGU/B". It is a steam generator with a burner that can work with different fuels (diesel oil or natural gas) with control over the working temperature, which generates steam quickly.

When the steam is generated at the working pressure and temperature conditions (superheated steam), it is driven to a turbine after passing through a droplet separator. Before being introduced in the turbine, a set of sensors gathers the values of the steam pressure, temperature and flow and transfer the information to the computer. The turbine is supplied with two generators and the rotation of the turbine vanes generates the electrical current thanks to the motion transferred by the shaft to those generators, coupled to both sides of the turbine. Two working modes are available: an isolated working mode, in which a group of variable resistors consume the electrical energy produced by the generator coupled to the turbine, and a grid synchronization working mode, in which all the electrical parameters (P, Q, S, f, etc.) supplied by the generator to the grid are measured.

The values of power and rpm are displayed in the computer, allowing the user to obtain the characteristic curves of the turbine: electrical power versus steam pressure, rpm versus steam pressure, power versus rpm, among other additional characteristic curves.

The turbine has a computer controlled speed. A pressure sensor and a temperature sensor measure the steam conditions at the outlet of the turbine. The steam coming out of the turbine is condensed in a heat exchanger and is recirculated to its inlet water tank by a computer controlled tank.

The pressure in the circuit at the outlet of the turbine is negative thanks to a vacuum system consisting of a vacuum pump and two tanks, making the pressure drops easier in the turbine.

The water of the second inlet tank (refrigeration circuit) is impelled by a computer controlled pump inside the turbine and condenser, acting as refrigerant in this circuit. Water coming out of the refrigeration circuit of the turbine and the refrigeration circuit of the condenser are mixed and, with higher temperature than at the beginning of the circuit, it is either drained or refrigerated by the Refrigeration Tower Unit, "RETU", OPTIONAL unit, and returned to the second inlet tank to reuse it.

The corresponding mass and energy balances, as well as the Rankine cycle representation and the calculation of the corresponding efficiencies in the main devices, can be done in the main devices of the unit.

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

Catalog (pdf) Tender Specifications (doc)